Lenzing Papier, manufacturers of Envirocare 100% Recycled and Impact, is not your average paper mill. Their tagline ‘Simply sustainable’ is in reality, what they live by. As a fully integrated paper mill with a minimal carbon footprint, they’re all about making the world a little greener, driven by the need to preserve the unspoilt natural environment of their Austrian mill’s site for current and future generations. We spoke to General Manager Ernst Brunbauer about the positive outcomes of a green approach.*

What does the Lenzing Papier mill do differently to other mills with regards to manufacturing paper?

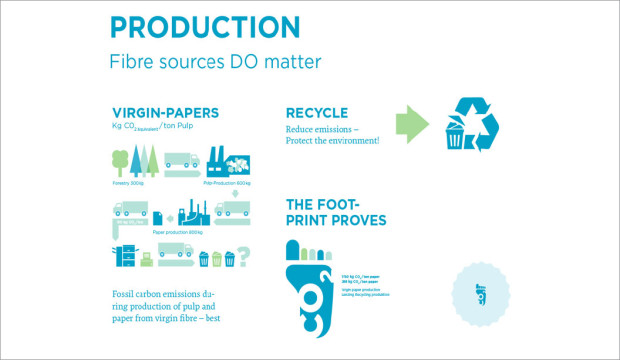

Paper mills making recycled products are usually not integrated with a pulp mill. Lenzing Papier is in a unique position as our mill is integrated with a de-inking plant and a pulp mill. There are two categories of recycled paper producers: the ones like Lenzing Papier, who operate their own waste paper facility and de-inking plant, and the ones who buy de-inked pulp on the market. Making the de-inked pulp in-house gives us a significant advantage in terms of avoided carbon emissions, because there’s no need to dry the de-inked fibres for transportation and shelf-life, as it’s made and used simultaneously. The fibres are made-to-measure for the paper machine and the respective product, giving a consistent output.

How can the mill’s carbon footprint be so small?

Predominantly because Lenzing Papier’s paper mill is integrated with the pulp mill (which is fairly uncommon), so we’re only using the carbon neutral energy from the pulping process. The pulp itself is a dissolving pulp grade used to make textile fibres and we use this energy, which is a side product of making dissolving pulp. The carbon footprint is very low because the energy is from renewable sources.

How many people work at the mill?

There are 160 people working in Lenzing Papier and most of them live in the area. The company was founded in 1892 and we have fourth and fifth generation employees.

What does the company primarily stand for and believe in when it comes to the environment?

The staff of Lenzing Papier loves nature. Most of our employees enjoy the outdoors and so their attitude towards protecting the environment is natural. They have a lot of pride in their work and want to be the best in environmental performance. Continually improving processes is an ongoing task for us and we believe in gentle chemical technologies, where nature is our guide, such as using enzymes instead of conventional chemistry.

Is this how you de-ink your pulp?

The de-inking process is usually done by using a flotation system in combination with air and de-inking chemicals to flotate the printing. At Lenzing we have developed a process using enzymes instead of the standard chemistry with very good success.

How much paper do you produce each year?

With a production of 85.000 metric tons per year, Lenzing Papier is a small paper mill compared to commodity producers, but it’s among the market leaders in the field of uncoated recycled papers.

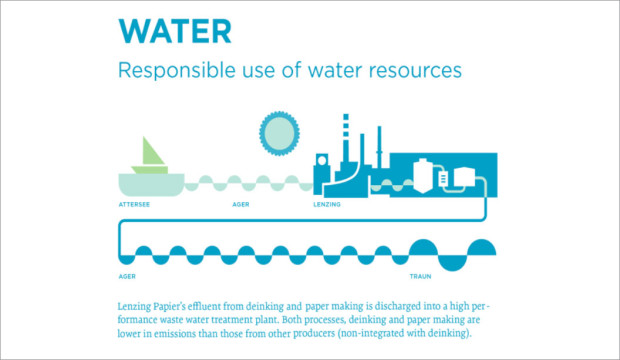

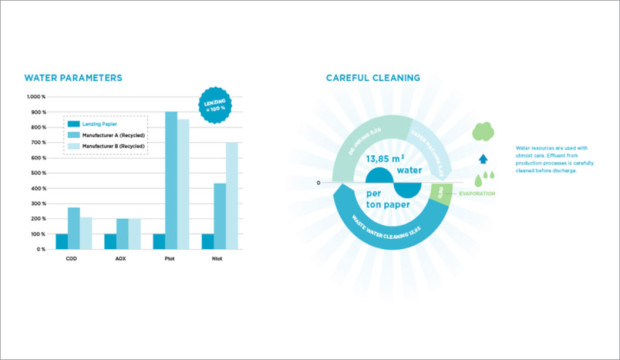

Is it true you swim in the same lake the water from the mill is pumped into?

Yes, that’s true. We take all our fabrication water out of the lake’s outflow and use it with only mechanical cleaning for production. After responsible use and careful cleaning of the water, we put it back into the river. People swim and fish after the outlet from the waste water treatment plant.

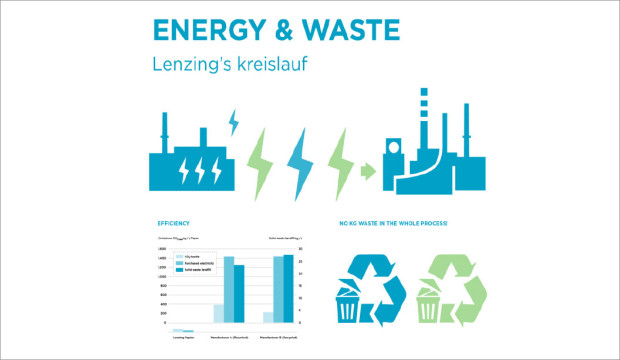

How much waste does the mill actually produce?

We’re very proud of the fact that we do not produce any waste that has to go to landfill. The raw materials are re-used as much as possible and at the end of their lifecycle those substances are incinerated in a very efficient incinerator. The generated energy is then put back into the milling process.

*Interview first appeared in the April 2017 issue of Spot, our print publication about paper, people, dogs and design.

Footy Tips

Footy Tips